Chemical Vapor Deposition Equipment Price

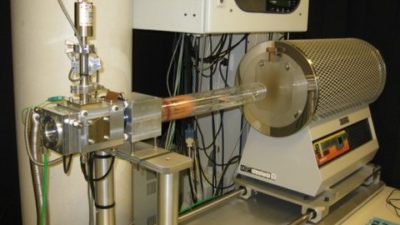

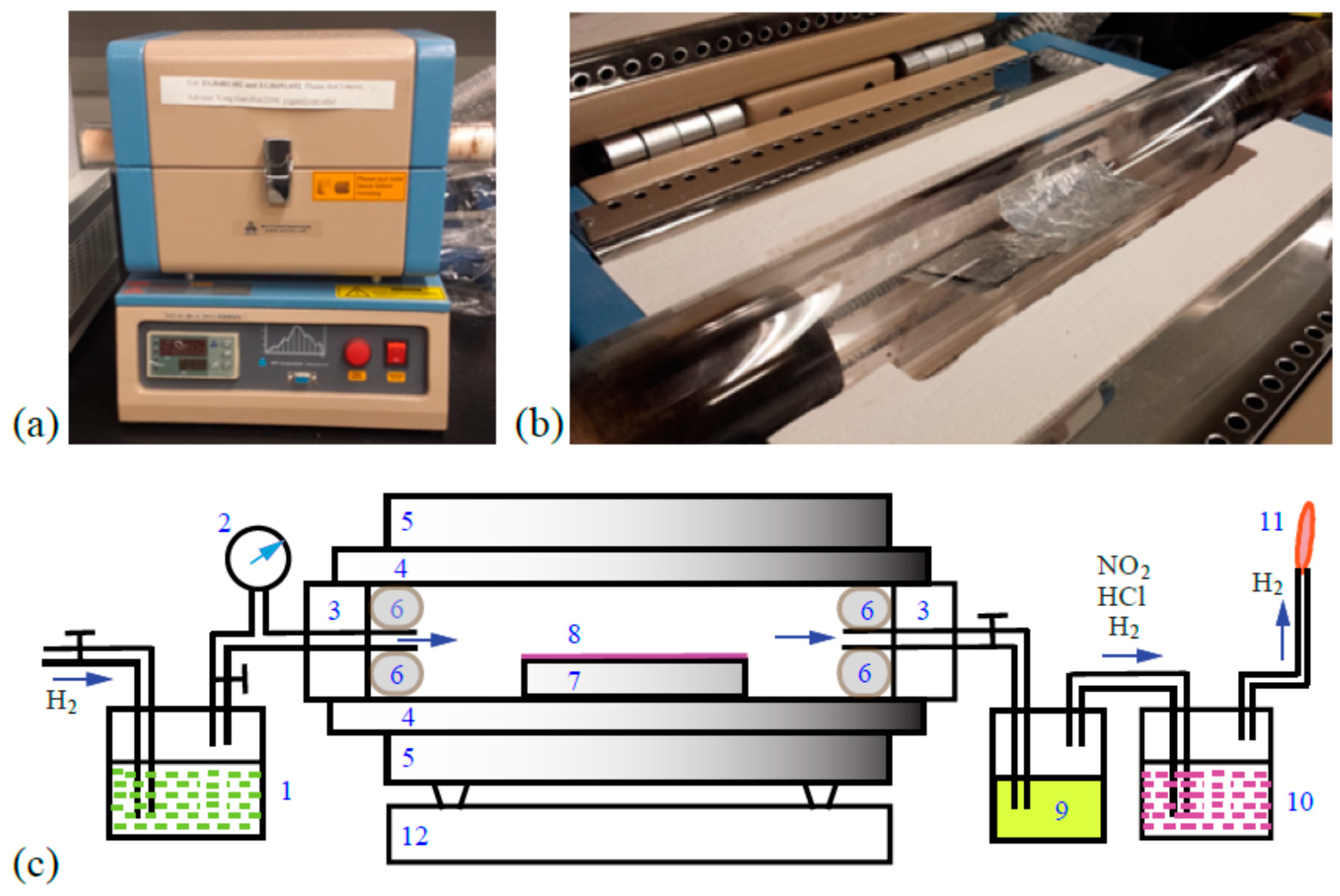

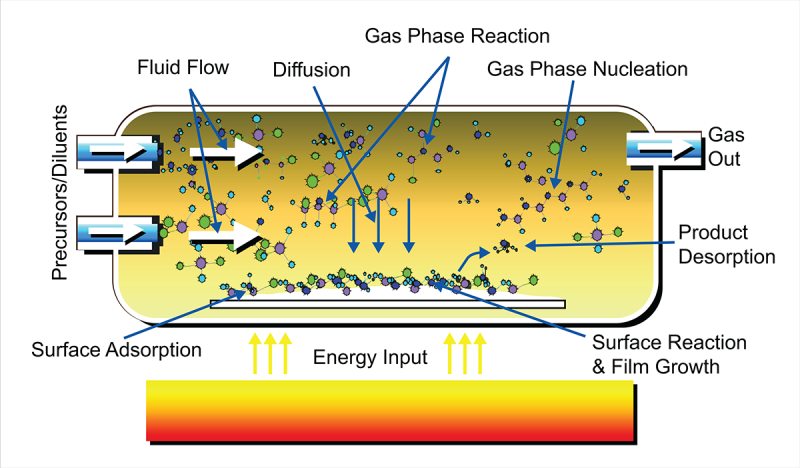

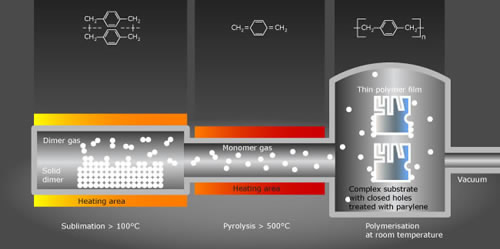

In typical cvd the wafer substrate is exposed to one or more volatile precursors which react and or decompose on the substrate surface to produce the desired deposit.

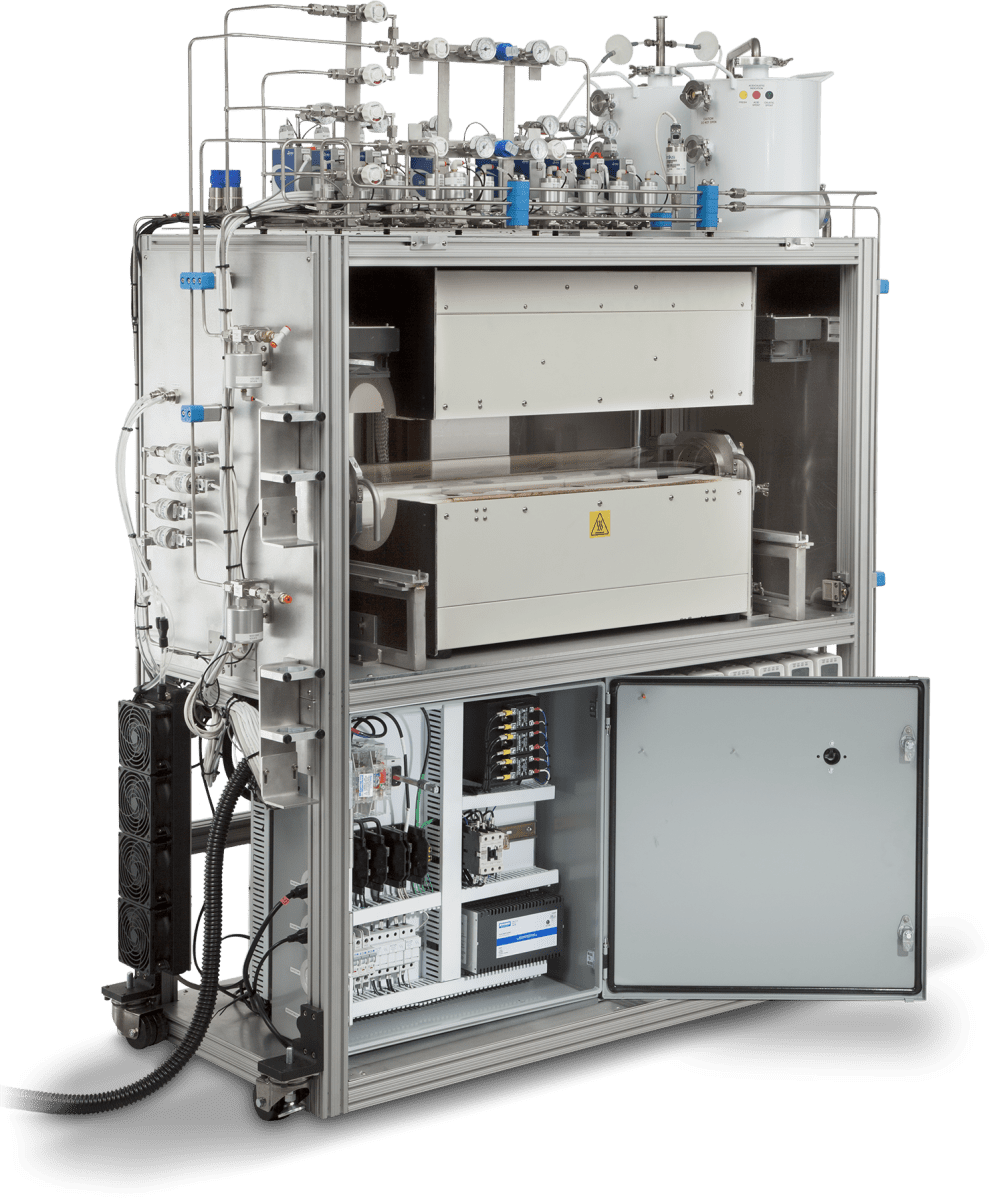

Chemical vapor deposition equipment price. Semiconductor chemical vapor deposition cvd equipment market is anticipated to witness a cagr of 8 5 over the forecast period 2019 2024. The surge in the growth plan for nano semiconductor. Substrate sits directly on electrode which can be heated up to 1200 c. Custom manufacturer of chemical vapor deposition cvd systems including belt furnaces.

We also provide r d systems to university government and private research laboratories worldwide. Anyone have an idea about the average price of an equipment xps. A very compact multifunctional chemical vapor deposition cvd reactor for. D x 8 in.

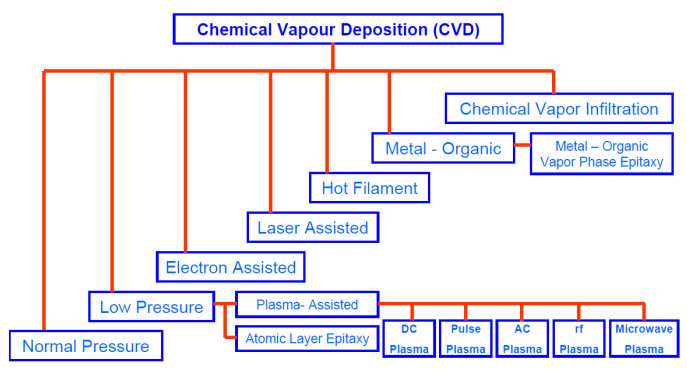

The company offers chemical vapor deposition systems for use in the research development and manufacture of aerospace and medical components semiconductors leds carbon nanotubes nanowires solar cells and other industrial applications. Plasma assisted chemical vapor deposition coating equipment ask price pacvd equippacvd equipment ionbond s bernex plasma assisted chemical vapor deposition pacvd or pecvd coating equipment allows for the deposition of extremely smooth amorphous diamond like carbon adlc coatings at temperatures under 200 c. Our products consist of a complete array of chemical vapor deposition systems. And rapid thermal processing systems for use in implant activation oxidation silicide formation and.

Chemical vapor deposition cvd is a vacuum deposition method used to produce high quality high performance solid materials. Cvd equipment corporation has been providing industrial coatings systems for over 35 years. Uhv chamber for surface science analysis. 2 analysis about the global metal organic chemical vapor deposition mocvd equipment market trends yearly estimates and cagr.

1 the metal organic chemical vapor deposition mocvd equipment market overview on the global platform and related technologies that will trend during the coming years. H to 80 in. The process is often used in the semiconductor industry to produce thin films. H sizes graphite hot zones up to 3000 degrees c resistance to heat.

D x 120 in.